Why does the government require me to do all this extra stuff?

Short History: In 1918 the most common shipping containers were wood crates, kegs & barrels. They used straw and even popcorn for cushioning; corrugated boxes; vapor barrier materials, and foam cushioning didn’t exist.

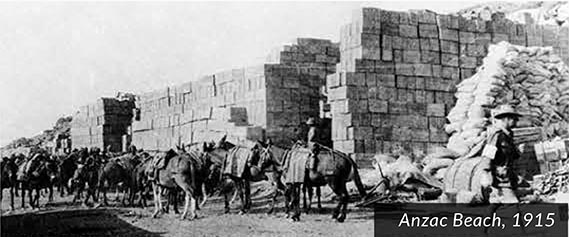

Once we hit the beaches in Europe our Army quickly realized there was a problem. We lost arms, ammo and supplies to sand, humidity and storms. Commercial packaging and cushioning couldn’t prevent damage and corrosion. The supply chain broke down and lives were lost.

At the beginning of World War II the same problem hit the Army in Iceland and the Navy at Guadalcanal. The military sustained high levels of supply and troop losses because of inadequate commercial packaging. Thus the evolution of military packaging began. The Dept of Defense developed specifications & training internally; while Industry & Government organized NIPHLE to meet and discuss continuous improvement for an ever changing combat world.

Mil Standard Packaging Mission

Preserve, Protect and Perform so the war fighter gets what they need.

It’s that simple…Packaging Matters.

WHY ACTIONPAK?

With over four decades of experience we know how to help you win contracts and comply with all the complex packaging, labeling and shipping requirements. If you choose to work with us your shipments will move faster while saving money. Our DOD Team have gone through Military Packaging School Training. Spend your valuable time making and sourcing products not packaging. We’ll help you through the process from contract bidding to final acceptance, inspection and sign off.

Recently Awarded Corporation of the Year for Outstanding Performance

We are well known in our industry and respected for our innovation and knowledge. ActionPak is also a Board Member & Corporate Training Sponsor

GOVERNMENT CONTRACT SPECIALISTS

Experts in all aspects of MIL-STD-2073 , ASTM-D-3951 and MIL-STD-129 marking. Controlled ESD & Clean Work Areas for Sensitive Electronics. Resident Government QAR on Premises for timely inspection and sign off. Providers & Preparation of WAWF (DD250) Submission used for Receiving Reports, Billing, & Advanced Shipping Notices (ASN). Class A Rated for GBL Application, Logistics & Transport Support.

Suppliers of Bar Code LOGMARS , MSL , RFID, IUID & UID Labels. Compliant with MIL-STD’s 129 & 130 for Markings

On Site Material & Box Shop for Crating using ISPM-15 (no bug) HT Lumber. Export & Consolidation Point for FMS Packing and Containerization. Heavy Lift Capabilities including on site Crane Services. HAZMAT Trained for Packaging & Ship Documentation over Land, Sea & Air

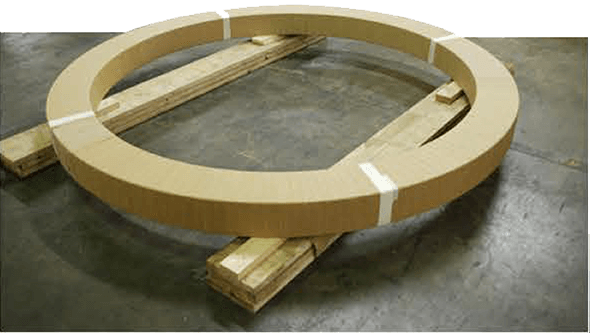

Clean Rooms I/AW FED-STD-209 For Bearings & Critical Components We are unusual. Our class 10,000 and 100,000 rooms are certified and on site to package bearings, pillow blocks, and part kits that require special MIL-DTL-197 processing & oxygen cleaning requirements. If your a supplier whose bidding these types of items please call us before you bid, not after.

Do you need DOD compliant packaging materials and labels? Confused about new Mil-Spec requirements or have you decided to keep it in house? Ask Us! We design complete packaging kits and stock a full line of materials including wraps, bags, cushioning, tapes, foam-n-place and various containers made from corrugated, wood, plastic and metal. Do you need help interpreting SPI’s: Special Packaging Instruction Details. We can even provide special containers using die cut foam to meet complex designs.